SAFETY SERVICES

Safe industrial machinery at every step of its lifecycle

functional safety for industrial machinery

Safety is our day-to-day business – and has been for more than 30 years. Wieland Electric personnel know the safety standards and know the capabilities of current and emerging technology in relation to standard control and safety control.

Functional safety is a component of a machine’s safety-related control system (SRCS). Wieland Electric provides safety control and services for various industrial machinery.

Our safety specialists develop comprehensive safety procedures – complying with the appropriate local and global laws and regulations – and offer the necessary hardware, software, and coaching to ensure optimal functional safety. We support you from the outset and provide expert guidance every step of the way. Whether it’s training, one-on-one consultations, or full project implementation — you decide how much support you need.

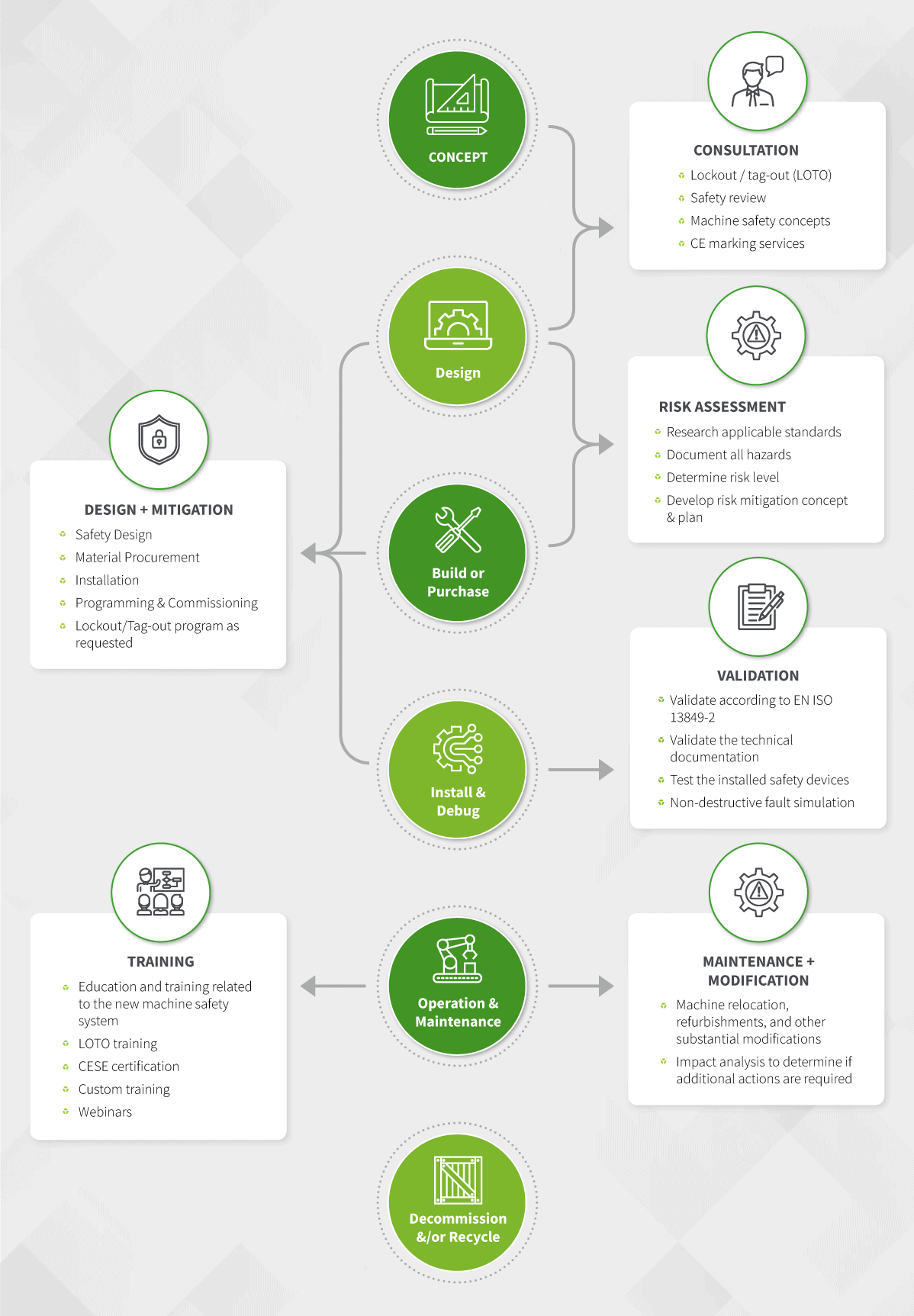

safety Solution Planning

With Wieland Electric, your organization can have a turnkey safety solution, with support from early evaluations through final commissioning. We can give a detailed plan for all phases, no matter where you are in the machine safety guarding process.

Services we offer

SAFETY CONSULTATION

Experienced Wieland Electric machine safety consultants provide expert guidance on safety reviews, lockout/tag-out planning and training, the machine safety concept, and the necessary reports for the CE mark certification process. Over a dedicated meeting and assessment, the safety expert will walk you through the requirements and the next steps. Depending on the project, some consultations can be completed virtually while others require a more detailed in-person assessment.

Services:

Lockout / tag-out (LOTO)

Safety review

Machine safety concepts

CE marking services

RISK ASSESSMENT

The Risk Assessment is the first phase of any safety system upgrade. The information determined in the Risk Assessment will be used during the different phases of the safety system upgrade. Wieland will create a guideline compliant risk assessment, complete with documentation that is in compliance with the current local & global laws and standards. The risk assessment includes research on the applicable standards, documentation of all hazards and likelihood of occurrence, determination of risk level (such as PLr), and the development of the risk mitigation concepts & techniques.

Includes:

Research applicable standards

Document all hazards

Determine risk level

Develop risk mitigation concept & plan

DESIGN + MITIGATION

The machine safety expert will provide safety system architecture recommendations and design, including turnkey integration services.

Includes:

Safety Design

Material Procurement

Installation

Programming & Commissioning

Lockout/Tag-out program as requested

VALIDATION

To confirm that the safety system achieves the safety performance level determined by the risk assessment, we will run the appropriate tests, check against the standards, and provide documentation.

Includes:

Validate according to EN ISO 13849-2

Validate the technical documentation

Test the installed safety devices

Non-destructive fault simulation

MAINTENANCE + MODIFICATION

Machine relocation, refurbishments, the addition of a new energy source, and other substantial modifications require that the safety concept be reanalyzed. Wieland will do an impact analysis to determine if the machine continues to comply with the appropriate safety guidelines.

Includes:

Machine relocation, refurbishments, and other substantial modifications

Impact analysis to determine if additional actions are required

Custom Training

Wieland Electric offers courses on the basics of functional safety for machinery, advanced certificate courses, and any custom training in-between that is specific to your situation.

CE MArking process

The CE Mark of conformity is your machine’s passport in to the EU. If you are selling or installing your machine in the EU you need to have a CE mark.

In practice, CE marking – and thus compliance with European legislation – is associated with many difficulties for machine builders, especially when it comes to modifications or convertions of a machine. Failure to comply with the Machinery Directive (MRL) 2006/42/EC can damage your company’s reputation and business activities and result in fines and criminal penalties for personal injury to non-compliant machinery.

Our safety experts will help you with the CE process from the initial risk assessment to the final checks and reports for the issuing of the CE declaration of conformity.

Lockout / Tagout (LOTO)

Lockout / tagout refers to the specific practices and procedures that safeguard employees from the unexpected energization or start-up of machinery and equipment, or the release of hazardous energy during service or maintenance activities. OSHA and ANSI both require a lockout / tagout program to protect workers from hazardous energy. Wieland can support you in creating a LOTO program, or Audit the program in place.

LOTO Training

Additional training can be provided to your maintenance team on the lockout / tagout program. The training is based on OSHA 1910.147, and ANSI Z244-1. Your EHS team can also be trained on the LOTO program requirements to ensure the health and safety of all of your employees.

Resources

SAFETY SERVICES BROCHURE

Certified Electrical Safety Engineer (CESE) bROCHURE

Functional Safety Standards Selection Poster

Samos Pro Compact

BOOK YOUR FREE CONSULTATION TODAY!

We understand the importance of taking the first step toward machine safety! That’s why we offer a free 30-minute consultation to help you get started. During this virtual meeting, our safety experts will listen to your concerns, and define the best approach to create your safety solution.